CNC Wire Forming Services & Custom Wire Solutions

Apex Wire Products Co., Inc. has specialized in precision custom wire solutions for over 80 years. Our manufacturing process includes CNC wire forming and wire straightening as well as complex assembly operations that require metal threading or brazing for demanding applications. Our Franklin Park facility near Chicago, Illinois operates with state-of-the-art equipment and manual inspection methods to guarantee all projects meet our quality and consistency requirements regardless of order size or complexity.

We take on projects from concept through final production, working directly with customers who expect quality parts, fast turnaround, and open technical communication. Our flexible wire fabrication systems are designed for both prototyping and high-volume runs, with traceable documentation at every stage. You’ll see our attention to detail in every part we deliver, and in the way we make sure your components perform where it actually matters: in real-world operation.

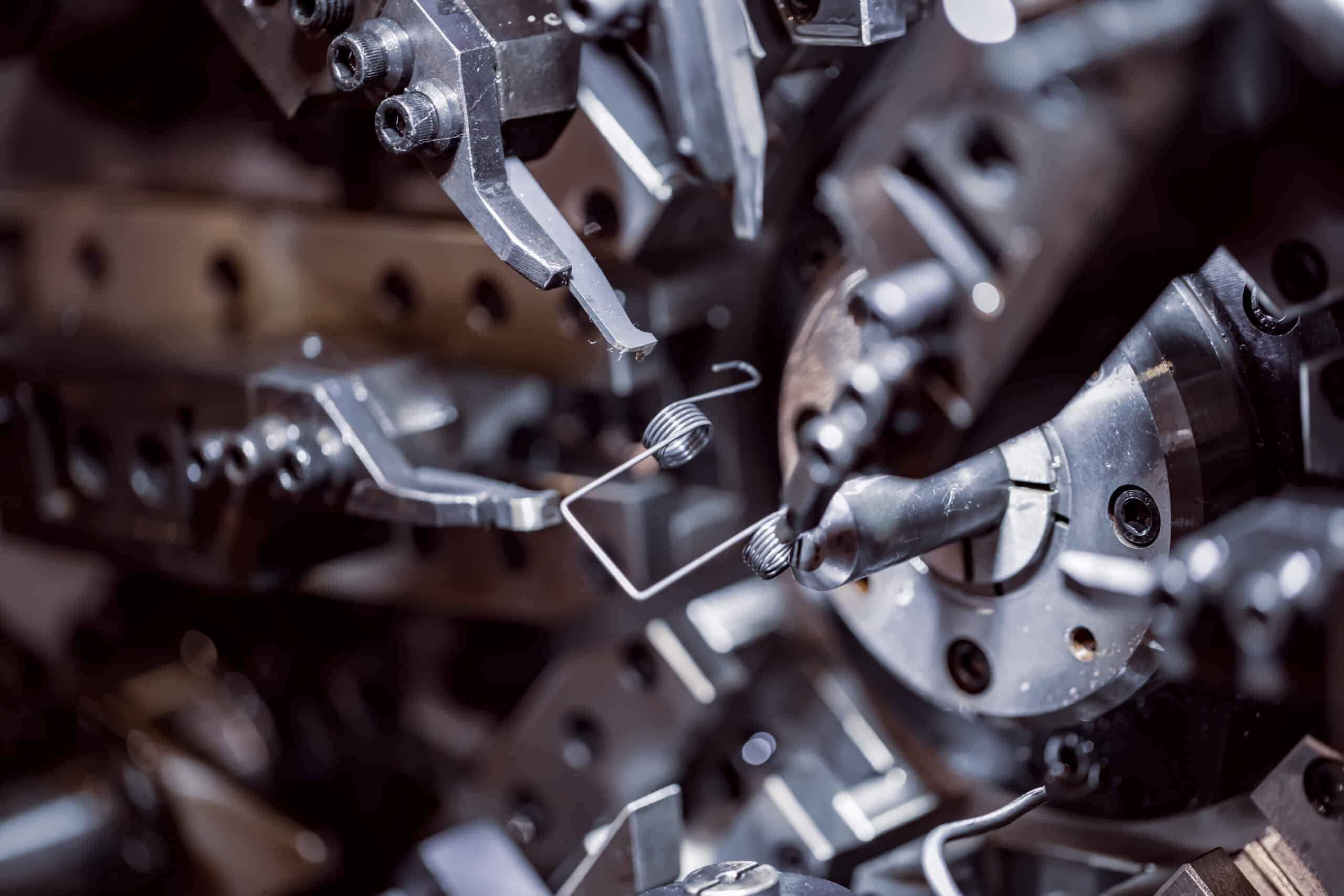

CNC Wire Forming Services

Our CNC wire forming services are at the core of what we do. We work with wire diameters from 0.015” to 0.472”, forming complex, multi-plane geometries with multi-axis CNC equipment. Our production capabilities include stainless, low carbon, and spring steels, as well as copper alloys, and specialty grades. Our in-house tooling and fixture design capabilities enable us to rapidly adjust to special shapes and part specifications. The automated production process maintains precise tolerances throughout the entire production run and every order includes complete traceability and quality assurance measures.

CNC wire forming capabilities include:

- Multi-axis forming for complex shapes

- Wire diameters from 0.015” to 0.472”

- Stainless, low carbon, spring steel, copper alloys, specialty grades

- Fast prototyping and scalable production

- Complete material and process documentation

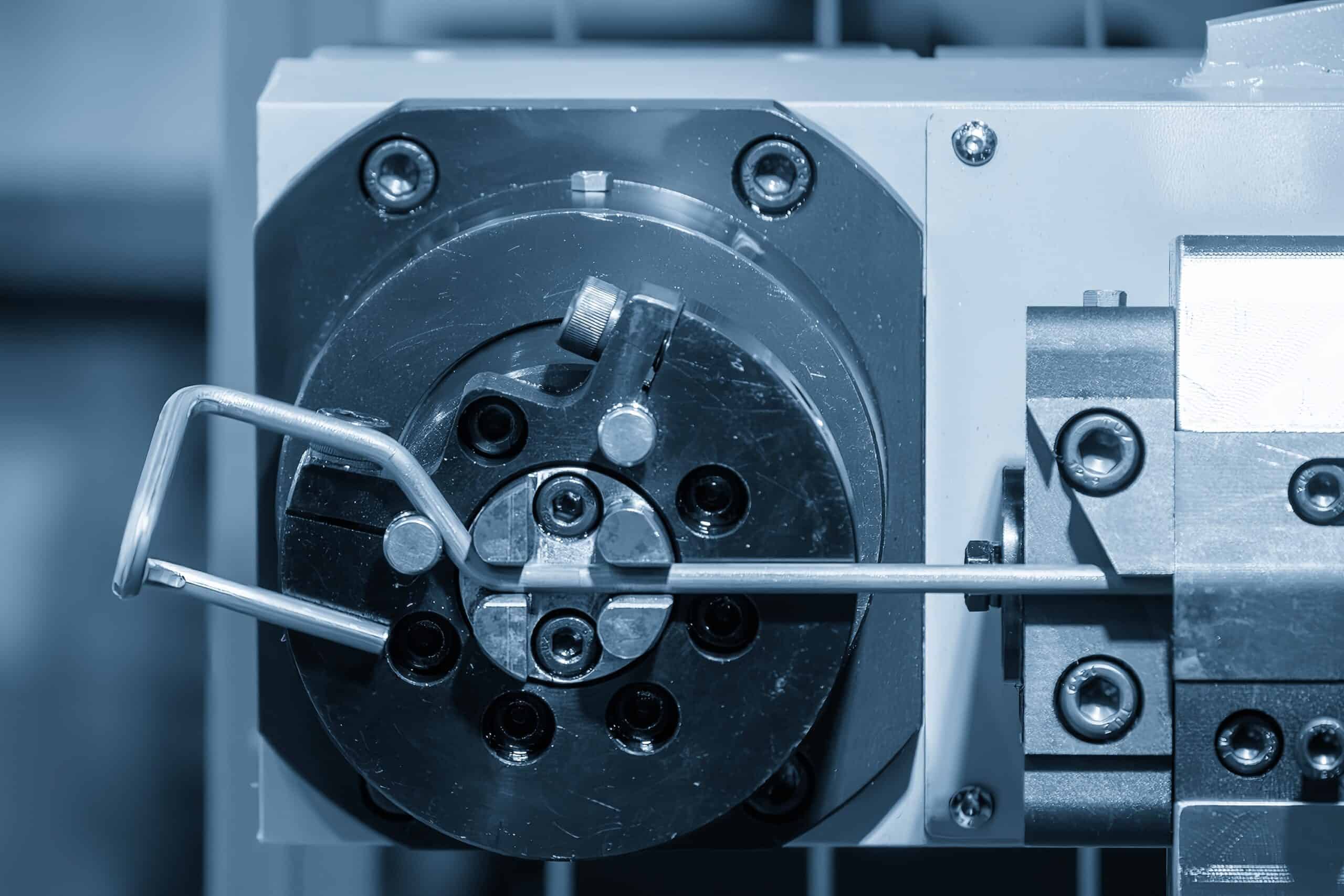

Metal Brazing, Welding & Metal Threading Services

We offer complete assembly and joining solutions to finish your wire products with precision and consistency. Our metal brazing services create strong, corrosion-resistant joints that are ideal for high-stress or high-temperature environments. For applications that require structural strength and conductivity, our in-house MIG, TIG, and resistance metal welding services deliver high-integrity bonds across a range of materials and geometries.

Whether it’s spot welding for wire mesh or TIG welding for tubular assemblies, our expert team ensures each weld meets your quality and performance standards. We also provide metal threading services, including both standard and custom profiles, as well as subassembly, secondary finishing, and application-specific process recommendations. Keeping all these services in-house helps reduce lead times, improve quality control, and simplify your supply chain by consolidating production with one trusted partner.

Joining and threading capabilities:

- Metal brazing for high-strength, leak-resistant joints

- MIG, TIG, and resistance metal welding services

- Metal threading (standard and custom threads)

- Subassembly, secondary finishing, and quality checks

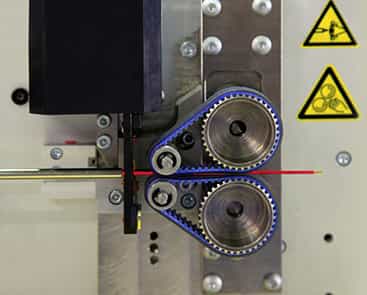

Wire Straightening & Cutting

Wire straightening and cutting are essential for dimensionally accurate parts. Our equipment produces straightened and cut-to-length wire in diameters from 0.015” to 0.500”, processing both common and specialty metals. Each batch is inspected for straightness and length accuracy, ensuring your blanks are ready for forming, threading, welding, or final assembly. Our quality checks and traceability ensure each order meets your exact project specifications.

Wire straightening & cutting services:

- Precision straightening and cut-to-length

- Diameters 0.015”–0.750”

- All industrial and specialty metals

- Prototypes to high-volume runs

- Inspection and traceability on every order

Start Your Project with Apex Wire Products

When you need CNC wire forming services, metal brazing services, metal threading services, or wire straightening from a team with real experience and accountability, work with us at Apex Wire Products.

Contact us today to discuss your requirements or request a quote.

Project Gallery

- Forming of a Joist Bracket

- Press Brake Forming of a Stainless Steel Coffee Basket

- Forming of a Horizon Cradle

- Forming of a Bolt

- Forming of a Steel U Bolt

Forming of a Joist Bracket

Forming of a Joist Bracket for the Lighting Fixture Industry

At Apex Wire Products Co., Inc., we manufacture multiple types of custom wire forms for the lighting industry. This project demonstrates our 3D wire forming and eye forming capabilities.

Read the full project >Press Brake Forming of a Stainless Steel Coffee Basket

Press Brake Forming of a Stainless Steel Coffee Basket for the Hot Beverage Industry

With over 70 years' of experience, at Apex Wire Products Co., Inc., we provide high quality forming of most any custom wire fabrication. We not only provide bending and forming services, but have the capability to machine, weld, and finish a wide range of products to exact customer specifications.

Read the full project >Forming of a Horizon Cradle

Forming of a Horizon Cradle for the Educational Purpose Industry

We work with a diverse array of customers to provide unique round and flat wire fabrications in a range of production volumes. The cradle houses a map and is used as a teaching tool.

Read the full project >Forming of a Bolt

Forming of a Bent Bolt for the Transportation Industry

We specialize in the turnkey fabrication of a variety of wire products. This custom bent bolt measures 6" in length by 3.75" in width and is used by a customer in the transportation industry.

Read the full project >Forming of a Steel U Bolt

Forming of a Steel U Bolt for the Transportation Industry

The custom U-bolt is used on truck trailers. The 13.25" long and 7" wide bolt is cut from 0.75" diameter A36 hot rolled steel round wire. The bolt is hand formed to within ±0.0625" using our hydraulic bending equipment and is threaded at both ends.

Read the full project >